Prototype Manufacturer - Shaping the Future of Product Development

In today's ever-evolving market, the necessity for a prototype manufacturer has never been greater. The rapid acceleration of technology and consumer demands calls for businesses to innovate continuously, and prototyping is a vital step in ensuring that new products meet market needs. This article will delve into the essentials of prototype manufacturing, its benefits, and how it plays a crucial role in various industries.

What is Prototype Manufacturing?

Prototype manufacturing refers to the process of creating a preliminary model of a product. This model serves as a proof of concept that allows designers and engineers to evaluate and refine the product before it goes into full-scale production. In essence, it is the bridge between an imaginative idea and a tangible product.

The Importance of Prototyping in Product Development

Prototyping offers numerous advantages across the product development lifecycle:

- Validation of Concept: Testing the feasibility of design ideas and functionality.

- Risk Mitigation: Identifying potential flaws or issues before mass production.

- Cost Efficiency: Saving money by avoiding expensive production errors.

- User Feedback: Gaining insights from potential users to improve design.

- Accelerated Time to Market: Streamlining the development process for quicker launches.

Types of Prototyping

Different types of prototypes serve various purposes throughout the development process. Below are some commonly used types:

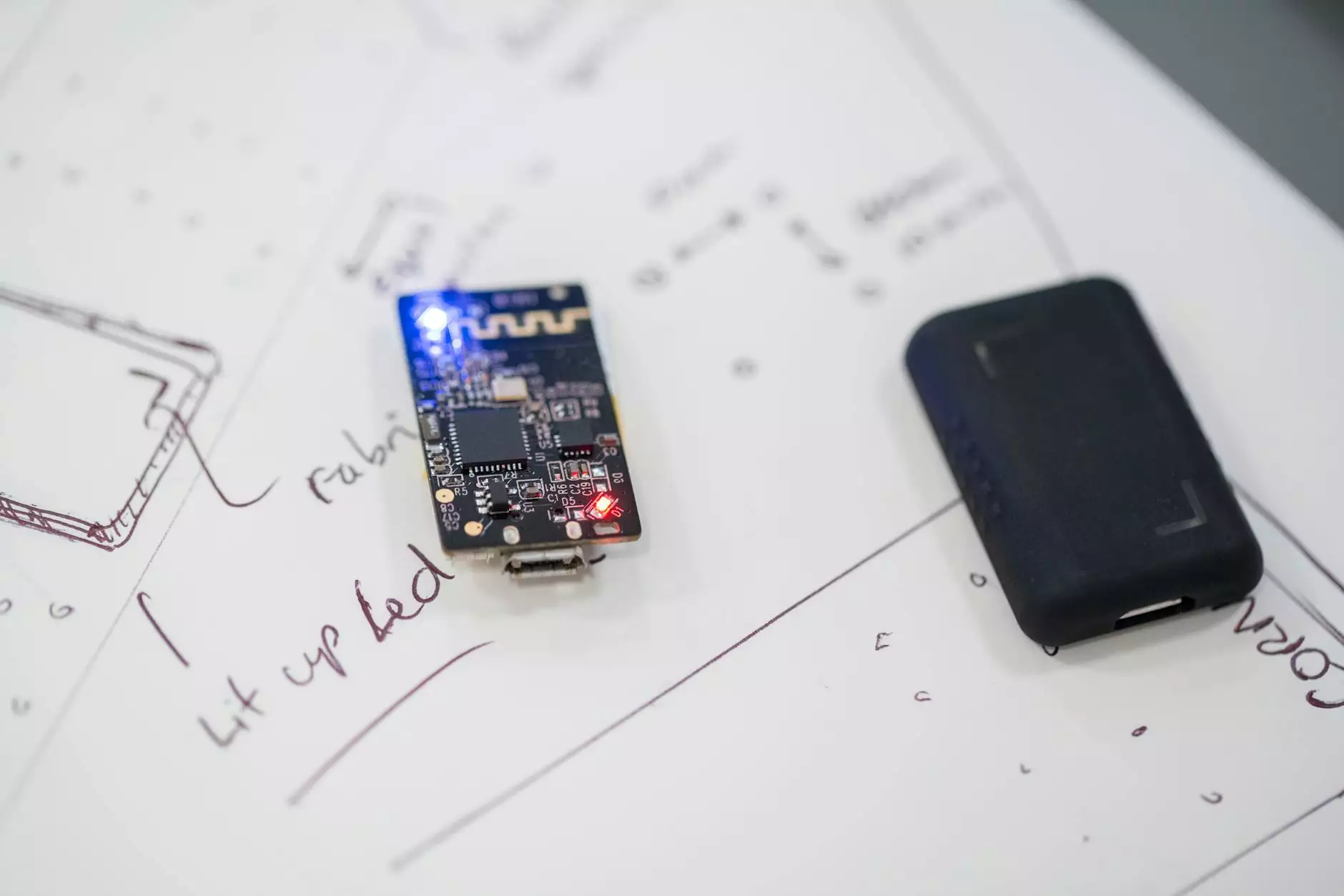

1. Visual Prototypes

These prototypes are primarily designed to showcase the look and feel of the product. They are crucial for gaining stakeholder buy-in and are often used in presentations.

2. Functional Prototypes

A prototype manufacturer often focuses on functional prototypes that demonstrate how a product operates, allowing for testing of usability and functionality.

3. Full-Scale Prototypes

These prototypes are built to the final size and appearance but may not represent the final material or production methods. They are used primarily for performance testing.

4. Virtual Prototypes

Using advanced software, these prototypes allow for the simulation of a product, identifying design flaws without physical creation.

Choosing the Right Prototype Manufacturer

Selecting the right prototype manufacturer is a critical decision that can significantly impact the success of your project. Here are key considerations when choosing a manufacturer:

- Experience and Expertise: Opt for manufacturers with a proven track record in your specific industry.

- Technology Capabilities: Ensure they utilize modern technology and methodologies suitable for your product.

- Material Knowledge: They should have expertise in various materials to offer the best options for your prototype.

- Quality Control: A robust quality assurance process is vital to ensure the prototype meets all specifications.

- Support and Communication: Choose a manufacturer that provides comprehensive support and maintains transparent communication throughout the process.

The Prototyping Process

The journey of prototyping involves several meticulous steps that lead to the realization of a vision:

1. Ideation and Conceptualization

It all begins with brainstorming and gathering ideas. This stage involves collaboration between various stakeholders to define the product's goals, features, and target audience.

2. Design and Planning

Once the concept is established, the next step is to create detailed designs. CAD software is typically used to create 2D and 3D renderings, ensuring precision and clarity.

3. Prototyping

This is where a prototype manufacturer comes in. They utilize tools such as 3D printing, CNC machining, or injection molding to create the physical prototype based on the designs.

4. Testing and Evaluation

The prototype undergoes rigorous testing to assess functionality, usability, and performance. Feedback from this phase is vital for refining the product before mass production.

5. Revision and Finalization

Based on the feedback received, adjustments are made to the prototype. This iterative process may require several revisions to meet the specified requirements.

Industries Benefiting from Prototype Manufacturing

Prototype manufacturing is not limited to a single sector. Various industries leverage this technique to innovate and refine their offerings:

1. Automotive Industry

In automotive manufacturing, prototyping helps test safety features and design elements, leading to better-performing and safer vehicles.

2. Consumer Products

From electronics to kitchen gadgets, consumer product companies utilize prototyping to understand user interactions and preferences.

3. Healthcare

Medical device manufacturers rely heavily on prototypes for testing new devices and ensuring they meet regulatory standards.

4. Aerospace

In aerospace, prototyping is essential for developing advanced technologies while adhering to stringent safety regulations.

5. Wearable Technology

The rise of wearable devices has created a demand for quick iterations and user-centered designs, making prototyping invaluable.

Future Trends in Prototype Manufacturing

As technology advances, the landscape of prototype manufacturing is set to evolve even further. Here are some anticipated trends:

- Increased Use of 3D Printing: Enhancements in 3D printing will allow for quicker and more cost-effective prototyping.

- Integration of AI: Artificial intelligence will enable better design optimization and predictive modeling.

- Sustainability Focus: Manufacturers will increasingly use sustainable materials and methods to reduce environmental impact.

- Collaborative Prototyping: Enhanced software platforms will allow for more collaborative and transparent design processes within teams.

- Advanced Simulation Software: Software solutions will continue to evolve, offering more robust simulation capabilities, reducing the need for multiple physical prototypes.

Conclusion

In summary, the role of a prototype manufacturer is vital in navigating the complex world of product development. From validating designs to mitigating risks, prototyping enables businesses to innovate effectively and efficiently. As industries adapt to the fast-paced market demands, the significance of prototyping will undoubtedly continue to grow. By embracing advanced technologies and practices, forward-thinking companies can ensure they stay at the forefront of their industries, bringing innovative products to market quickly and successfully.

For more information about how a premier prototype manufacturer can assist you in your next project, visit deepmould.net. Together, we can shape the future of your product ideas.